![]() It’s honey harvest time when at least

It’s honey harvest time when at least

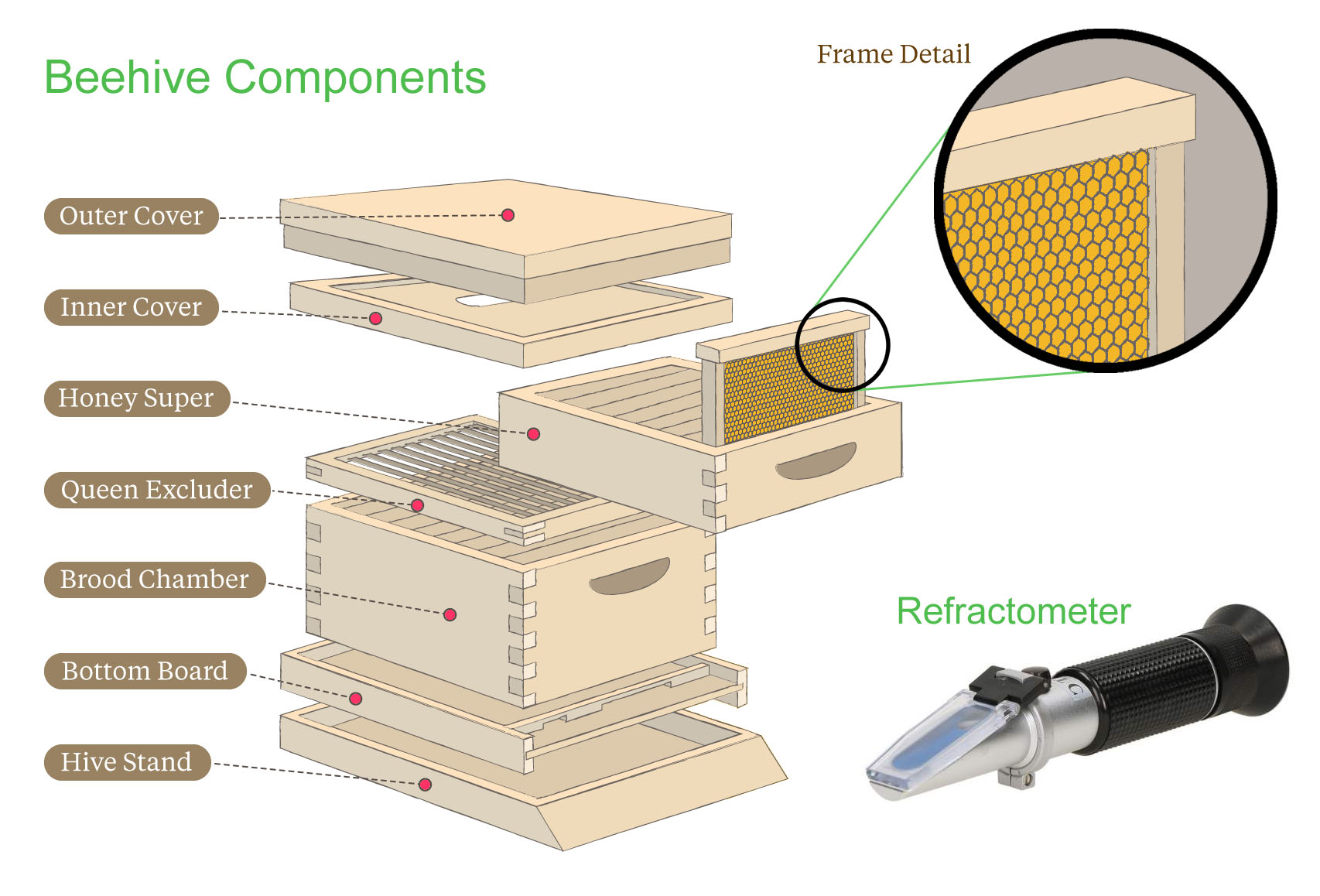

The bees in the hive fan the honey with their wings to lower the moisture content before each cell is sealed with wax — amazing!

The moisture content of the honey is measured by using a handy device called a refractometer.

In the field, a blower is used to remove excess bees from the

The supers are then transported to our honey processing facility and placed into a “warm room” for about 36 hours. This allows any remaining bees to join a temporary small hive, and the combs can soften for extracting.

Each frame of honey is sent through a

The frames proceed on a conveyor into a centrifugal extractor, where the honey is spun out.

Next the honey drains into a pumping tank to settle and separate from the beeswax. (Later the recovered beeswax will be used to produce our varied line of pure beeswax candles.)

Finally the honey is pumped into another settling tank to be strained through fine mesh, and then the honey is barreled.

Because our honey is not overheated or

In every step of our honey harvest and production, our goal is to maintain the highest quality and delicate flavor that our customers have long enjoyed. Each drop of Gentle Breeze Honey® is a celebration of the industrious collaboration of beekeeper and honeybees!

Loading Honey Frames for Extraction

Automated Cutting of Wax Cappings

Hand Scraping of Honeycombs

Centrifugal Extractor

Loading Honey Frames for Extraction

Automated Cutting of Wax Cappings

Hand Scraping of Honeycombs

Centrifugal Extractor